Intuitive & Interactive

Automation Control

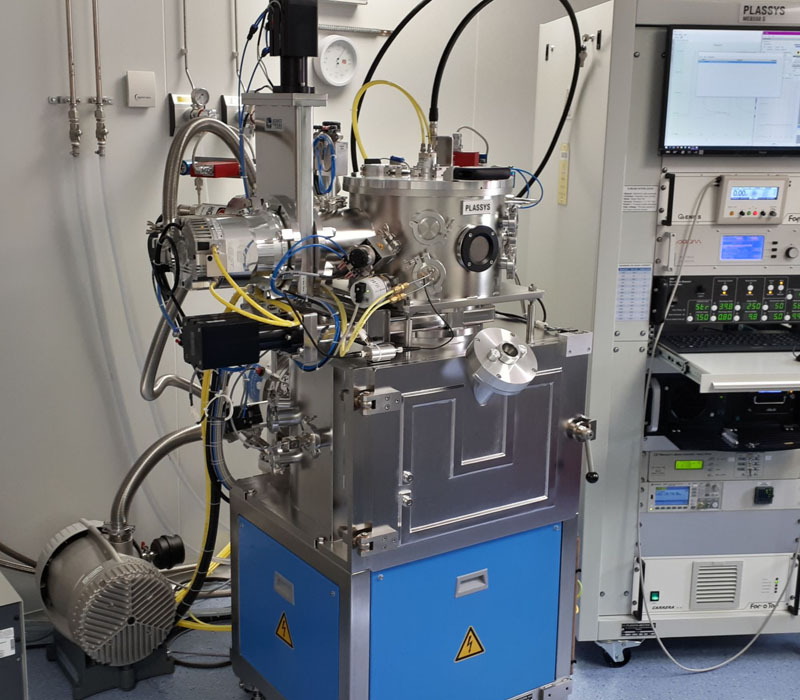

Every Plassys system is supported by rugged electronics automation system aptly supported by interactive and intuitive controls. Plassys offers two modes of control choices for the users to select, partially automatic and fully automatic.

Semi-Automatic Control System

- Economical semi-automatic control via binary logic relays or via automatized logic board.

- Suitable for R&D and or advanced users.

- Time tested & true feeling & confidence of button operation and dial reading from controllers.

- All electronics housed in a standard 19“ Industrial standard cabinet.

- Incorporates all the necessary safety protocols for the user and the machine.

- Button-dial interface which offers direct interaction with the machine is usually the mode preferred by R&D seasoned specialists.

- A portable computer can always be added for recording of data pertaining to the Inputs/ Outputs.

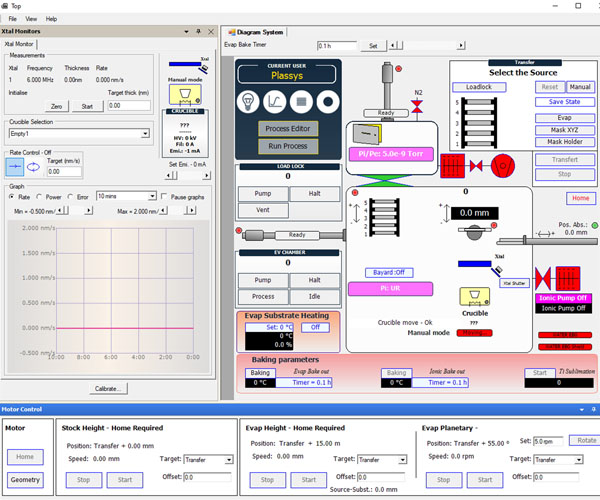

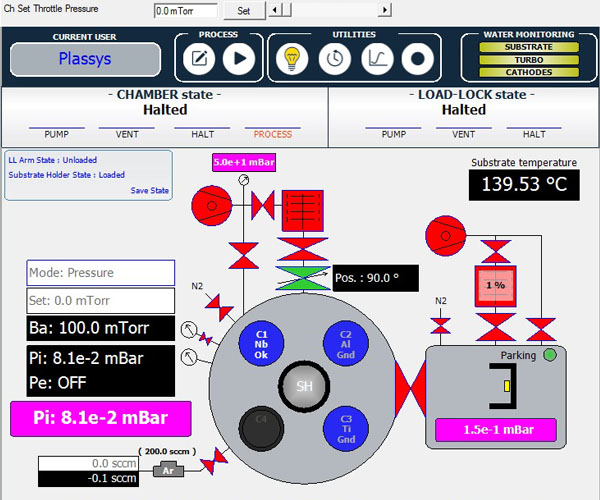

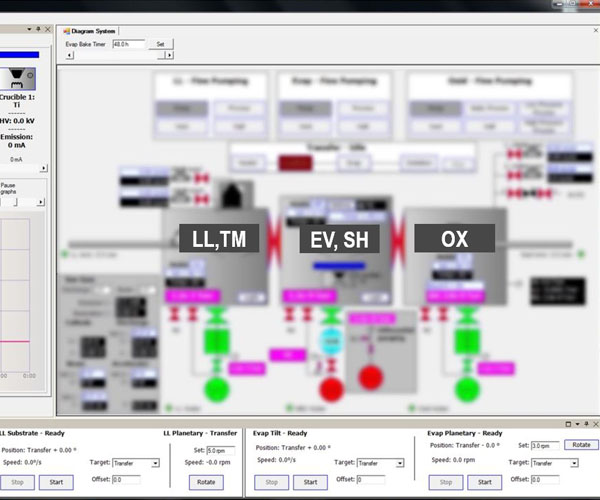

Fully Automated Control System

- Full system control by PC and custom software under Windows PRO.

- Industrial cabinet houses all electronics and computer for automation & control.

- RAID back up system incorporated in to the data storage.

- SCADA type software offer high level of stability, flexibility & adaptability.

- Custom designed software is very efficient, intuitive and user friendly.

- Its flexibility allows for easy modifications, tuning, and online troubleshooting.

- Interactive & Mimic screens specifically designed for different processes.

- Manual, automatic and semi-automatic modes of control.

- Recipe creation and execution (on-site and off-site).

- Analog and digital In/ Out data recording.

- Data export to Excel/ Origin/ Kaleida/ etc

- Continuous one-hour volatile memory of all the Input / Output.

- Multi-Level user identification and Access Control through password.

- Compatibility with other “Active X” prog languages like LabVIEW, MATLAB etc.

- Communication Interfaces like RS232, RS485, GPIB etc.

- Compatibility with any stand alone or industrial PC running with Windows Pro